Garment Production Software

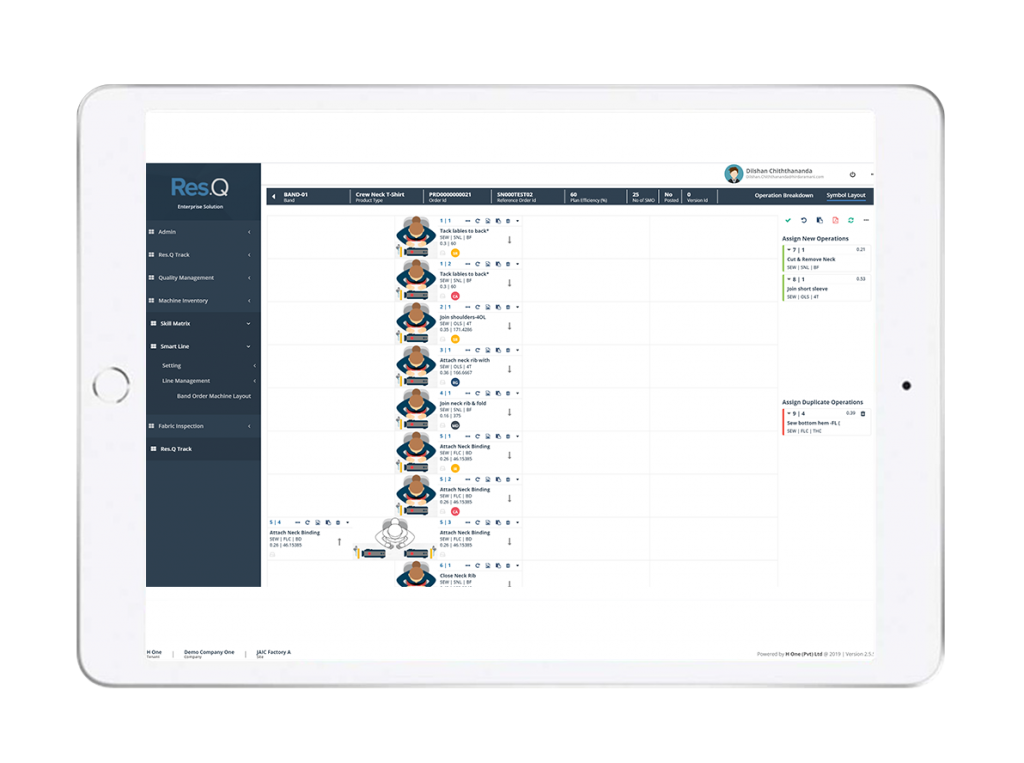

Res.Q | SL is an integrated line planning module, helping IE teams digitize the process of production line planning, line balancing and symbolic layout creating in a matter of minutes rather than hours.

What is Res.Q

SIMPLIFIED LINE BALANCING

Res.Q Smart line is a Garment Production Software with an integrated line planning module, helping IE teams digitize the process of production line planning, line balancing, and symbolic layout creation in a matter of minutes rather than hours.

Also through the integration of machine inventory and Skill matrix modules of Res.Q, Smart line is now able to help IE teams map the exact machine and operator for their, respective production lines for a much more precise & effective line planning, which could be done in a matter of minutes.

- Upload your Operation breakdown

- Integrate your method study

- Adjustable number of line operators

- Adjustable planned efficiency

- Autogenerated “tack-time”

- Adjustable “actual manning level”

- Auto generated pre-production yamazumi chart

CREATE LAYOUT TEMPLATES

Whether it is a simple straight line, a “U” shaped line or even a component line, Res.Q Smart Line is capable of generating the best line layout for your requirement.

- Dual operation identification

- Map Ironing and helping workstations

- Change operator seating orientation

- Fully editable line layout

- Workstation wise SMV display

MAPPING YOUR MAN AND MACHINE

MAPPING YOUR MAN AND MACHINE

Res.Q Smart Line taps in your employee skill resources to identify the best skilled operator suited to perform the listed operation in your layout and maps the operator and also the exact machine by taping in to the machine inventory module for a faster and effective layout planning process.

APPLICATION DRIVEN CAPACITY STUDIES

Conduct your post planning capacity studies through which Res.Q automatically identifies bottle necks and troubled workstations

- Application based capacity study

- Bottle neck identification

- Display operation SMV VS operator SMV

- Auto comparison of planned vs actual Yamazumi charts

- Perfect your layout

- Capture your line down time digitally